Giải pháp

Horse Construction cung cấp đầy đủ các loại vật liệu gia cố kết cấu với hỗ trợ kỹ thuật, hỗ trợ tài liệu, hỗ trợ sản phẩm, hỗ trợ phần mềm, hỗ trợ dự án.

Common Diseases and Reinforcement Methods of Shear Walls

Shear wall structures are widely used in high-rise buildings due to their excellent integrity and seismic resistance. However, issues such as insufficient concrete strength, reinforcement leakage, cracks, design defects, and artificial damage (such as unauthorized demolition of shear walls) can lead to insufficient bearing capacity, seismic resistance, and strength of shear walls, thereby affecting the overall and safety of shear wall structures.

So, how should shear wall structures be reinforced when their bearing capacity does not meet the requirements of the specifications or actual needs? Common reinforcement methods for shear walls include increasing section reinforcement method, pasting fiber composite material reinforcement method, pasting steel plate reinforcement method, changing structural system method, planting steel bar technology, etc. In this issue, we mainly introduce increasing section reinforcement method, pasting steel plate reinforcement method, and pasting carbon fiber mesh reinforcement method.

Reinforcement method with increased cross-section

The method of increasing section reinforcement is to increase the cross-sectional area of structural components or structures for reinforcement. It can not only improve the load-bearing capacity of the reinforced components, but also increase their cross-sectional stiffness and change their natural vibration frequency. It can have a significant seismic reinforcement effect on components with smaller column sizes or significantly higher axial compression ratios in the original frame. However, the drawbacks of this method are also relatively obvious, as the increase in the original components will lead to a smaller building space and affect the mechanical performance of other components.

Reinforcement technology description:

1. When the bearing capacity of the wall does not meet the requirements of the specifications, or when the wall size, reinforcement, and axial compression ratio do not meet the requirements of the specifications, or when the concrete strength of the wall is low or there are serious defects in the construction quality, the method of adding reinforced concrete post pouring layers on both sides, one side, or locally of the original wall can be used for reinforcement.

2. The thickness of the newly added concrete layer is determined by calculation and should generally be ≥ 60mm.

3. The strength grade of the newly added concrete should be increased by one grade compared to the original concrete, and should not be lower than C25 grade.

4. The specifications of the newly added steel mesh in the wall are determined by calculation, and in general, it should be: vertical steel bars ≥ Φ 10-12, spacing 150-200, transverse reinforcement ≥ Φ 8-10, spacing 150-200, with vertical bars inside and horizontal bars outside.

5. The newly added steel mesh should be reliably connected to the original wall, and can generally be connected by tie bars or planting bars. The specifications of tie bars and planting bars are generally taken as Φ 6-8, the spacing between tie bars is set at 900, and the spacing between planting bars is set at 600. Generally, a plum blossom arrangement is used.

6. The ends of the longitudinal and transverse steel bars should have reliable anchoring, which can be anchored to the adjacent components of the foundation, frame columns, shear walls, and floor slabs by planting steel bars.

Bonding steel plate reinforcement method

The bonding steel plate reinforcement method uses high-performance bonding steel adhesive to firmly bond the steel plate and concrete, and can effectively transfer stress to form a whole to work together, thereby improving the bearing capacity and stiffness of the bending components of concrete structures.

Reinforcement Technology Description

1. When the wall is only insufficient due to horizontal reinforcement, the method of pasting steel plates can be used for reinforcement, that is, setting horizontal horizontal flat steel on the surface of the wall. When the wall reinforcement is insufficient, the construction of pasting steel plates should not be implemented and should not be used.

2. The specifications and distribution of flat steel are determined by calculation, generally taking (80-120) * (3-4) @ 300-500. The flat steel should be anchored with chemical anchor bolts.

3. The end of the flat steel should have reliable anchoring. Generally, anchoring angle steel can be set at the intersection of the vertical and horizontal walls, and the flat steel should be welded to it. The welding position should be welded first and then applied/poured with structural adhesive.

4. The combination of flat steel and wall surface can generally be bonded with adhesive, but the welding area should be welded first, and then partially coated/poured with adhesive for bonding.

Reinforcement method using carbon fiber mesh reinforcement

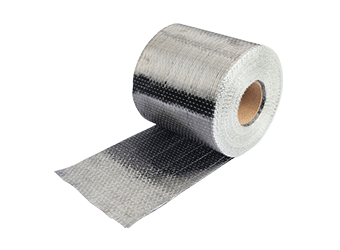

The carbon fiber mesh reinforcement system is a combination of carbon fiber materials and specialized wet sprayed concrete mortar, fully integrating the advantages of the materials to achieve the bonding of carbon fiber mesh and concrete components, forming a "sandwich" structure of mortar grid mortar, achieving the effect of joint stress.

The carbon fiber mesh reinforcement system has many advantages, such as good fire resistance, good breathability, good durability (without the problem of structural adhesive aging), corrosion resistance, and saving building space (with a single layer reinforcement thickness of only 15mm).

Reinforcement Technology Description

1. When the seismic resistance and crack resistance of the wall are insufficient, the wall is eccentrically compressed, or the concrete strength of the wall is insufficient, a carbon fiber mesh reinforcement system can be used for reinforcement.

2. The gripping force between carbon fiber and mortar is generally small. By applying a special interface treatment agent on the surface of carbon fiber, the gripping force between mortar and carbon fiber can be effectively ensured.

3. The thickness of mortar and the number of carbon fiber mesh layers can be determined based on the actual situation on site. Generally, the thickness of pasting a layer of carbon fiber mesh is about 15mm. And the carbon fiber mesh has excellent fire resistance performance, with a 1cm mortar protective layer reaching the 60min fire resistance standard.

Bạn có thể tìm thấy mọi thứ bạn cần ở đây. Hãy tin tưởng và thử nghiệm các sản phẩm này, bạn sẽ thấy sự khác biệt lớn sau đó.

Lớp bọc sợi carbon đơn hướng, cường độ cao được bão hòa trước để tạo thành lớp bọc polyme gia cường sợi carbon (CFRP) dùng để gia cố các cấu kiện bê tông kết cấu.

Dải / tấm polyme gia cường sợi carbon (CFRP) cường độ cao để gia cố kết cấu và sửa chữa bê tông

Keo liên kết tấm thép kết cấu HM-120 là sản phẩm epoxy hai thành phần, có độ bám dính mạnh, đóng rắn ở nhiệt độ phòng. Có đặc tính chống lão hóa, chống va đập tuyệt vời trong khả năng tự bám dính và bám dính lẫn nhau của thép và bê tông, với tốc độ cắt cao